By fuwaparts | 23 February 2024 | 0 Comments

The Science Behind Hydraulic Pumps in Crawler Cranes: A Deep Dive

Hydraulic pumps serve as the heart of numerous heavy machinery, with crawler cranes being one of the most prominent examples. These complex systems are not only a feat of engineering but are also crucial in providing the powerful lifting capabilities that are synonymous with crawler cranes. This deep-dive blog post will explore the intricacies of hydraulic pumps in the context of crawler cranes and shed light on how they are revolutionizing the industry.

Decoding the Mechanics of Hydraulic Pumps in Crawler Cranes

Hydraulic pumps are at the foundation of what makes modern crawler cranes the powerful lifting machines they are. These pumps are responsible for converting mechanical energy into hydraulic energy, which is then used to operate different mechanical features of the crawler crane.

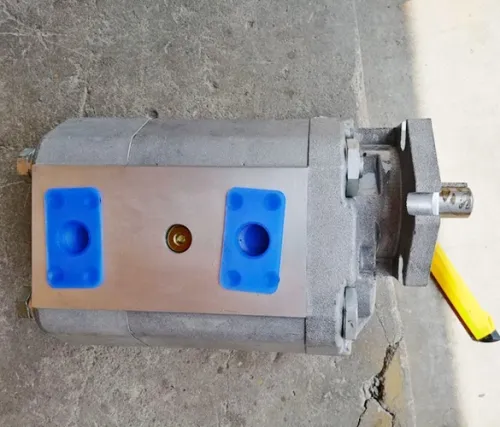

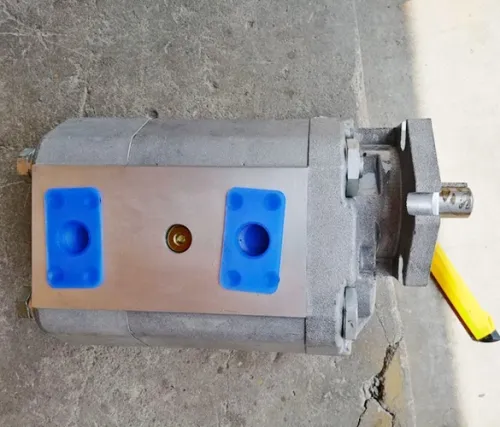

The design of hydraulic pumps varies, from gear pumps to piston pumps, each with its unique benefits and operating principles. For instance, gear pumps are known for their simple design and reliable performance, while piston pumps are valued for their higher efficiency and variable displacement capabilities.

In the context of a crawler crane, the type of hydraulic pump used can significantly impact the machine's overall performance and efficiency. By understanding the mechanics behind these pumps, crane operators, and technicians can optimize their usage to ensure smooth and powerful operations on the construction site.

How Hydraulic Pumps Revolutionize Crawler Crane Operations

Crawler cranes equipped with hydraulic pumps enjoy a host of advantages that are otherwise unachievable. These cranes can lift heavier loads, operate more precisely, and adjust to changing conditions with unparalleled flexibility. The key to these capabilities lies in the manner in which hydraulic pumps can deliver consistent pressure, flow, and control to the crane's hydraulic system.

This level of stability and control is essential during critical lifting operations where precision can mean the difference between success and failure. Additionally, the ability of hydraulic pumps to provide variable flow rates and pressure settings allows crawler cranes to adapt to various loads and terrain conditions, enhancing safety and efficiency.

The efficiency and power of hydraulic pumps are exemplified in the overall reduction of mechanical stress on the crane's components. This, in turn, translates to fewer maintenance requirements and a longer operational life for the machine.

Demonstrating Success: Case Studies on the Impact of Hydraulic Pumps

The impact of hydraulic pumps on crawler crane performance can be seen through multiple case studies. In construction projects where time is of the essence and lifting operations are frequent, the implementation of advanced hydraulic pumps has led to significant improvements.

For example, when used in the construction of high-rise buildings, cranes with powerful hydraulic pumps can handle the extreme heights and heavy materials with ease. This streamlines the construction process by reducing the number of lifting instances required and minimizing downtime due to equipment limitations.

Expert Insights: Maximizing the Potential of Hydraulic Pumps in Crawler Cranes

To unlock the full potential of hydraulic pumps in crawler cranes, it is essential to seek insights from industry experts. Regular maintenance and adherence to suggested operating parameters are vital to ensuring that the hydraulic system, including the pump, functions optimally.

Experts recommend a combination of best practices, such as monitoring hydraulic fluid condition, checking for leaks, and training operators on the nuances of the hydraulic system, to maintain peak operational efficiency. Furthermore, staying informed about the latest hydraulic pump technologies can provide a competitive edge in the construction industry.

Upcoming Developments in Crawler Crane Hydraulic Pump Technology

As with many fields, hydraulic pump technology for crawler cranes is constantly evolving. Manufacturers are continually exploring new materials, designs, and features to enhance performance and durability. The integration of digital controls and smart technologies is also on the rise, offering a new level of precision and automation to crane operations.

In addition, there is a growing focus on environmental sustainability, which is leading to the development of more energy-efficient hydraulic pumps. These "green" pumps not only reduce the carbon footprint of crawler cranes but also offer cost savings in the form of reduced fuel consumption and lower operating temperatures.

In conclusion, the role of hydraulic pumps in the operation of crawler cranes cannot be overstated. They are the unsung heroes that enable these magnificent machines to deliver the heavy lifting prowess that powers global construction projects. As technology advances and the construction industry continues to grow, the science behind hydraulic pumps will play an ever more critical role in shaping the future of crawler cranes.

Decoding the Mechanics of Hydraulic Pumps in Crawler Cranes

Hydraulic pumps are at the foundation of what makes modern crawler cranes the powerful lifting machines they are. These pumps are responsible for converting mechanical energy into hydraulic energy, which is then used to operate different mechanical features of the crawler crane.

The design of hydraulic pumps varies, from gear pumps to piston pumps, each with its unique benefits and operating principles. For instance, gear pumps are known for their simple design and reliable performance, while piston pumps are valued for their higher efficiency and variable displacement capabilities.

In the context of a crawler crane, the type of hydraulic pump used can significantly impact the machine's overall performance and efficiency. By understanding the mechanics behind these pumps, crane operators, and technicians can optimize their usage to ensure smooth and powerful operations on the construction site.

How Hydraulic Pumps Revolutionize Crawler Crane Operations

Crawler cranes equipped with hydraulic pumps enjoy a host of advantages that are otherwise unachievable. These cranes can lift heavier loads, operate more precisely, and adjust to changing conditions with unparalleled flexibility. The key to these capabilities lies in the manner in which hydraulic pumps can deliver consistent pressure, flow, and control to the crane's hydraulic system.

This level of stability and control is essential during critical lifting operations where precision can mean the difference between success and failure. Additionally, the ability of hydraulic pumps to provide variable flow rates and pressure settings allows crawler cranes to adapt to various loads and terrain conditions, enhancing safety and efficiency.

The efficiency and power of hydraulic pumps are exemplified in the overall reduction of mechanical stress on the crane's components. This, in turn, translates to fewer maintenance requirements and a longer operational life for the machine.

Demonstrating Success: Case Studies on the Impact of Hydraulic Pumps

The impact of hydraulic pumps on crawler crane performance can be seen through multiple case studies. In construction projects where time is of the essence and lifting operations are frequent, the implementation of advanced hydraulic pumps has led to significant improvements.

For example, when used in the construction of high-rise buildings, cranes with powerful hydraulic pumps can handle the extreme heights and heavy materials with ease. This streamlines the construction process by reducing the number of lifting instances required and minimizing downtime due to equipment limitations.

Expert Insights: Maximizing the Potential of Hydraulic Pumps in Crawler Cranes

To unlock the full potential of hydraulic pumps in crawler cranes, it is essential to seek insights from industry experts. Regular maintenance and adherence to suggested operating parameters are vital to ensuring that the hydraulic system, including the pump, functions optimally.

Experts recommend a combination of best practices, such as monitoring hydraulic fluid condition, checking for leaks, and training operators on the nuances of the hydraulic system, to maintain peak operational efficiency. Furthermore, staying informed about the latest hydraulic pump technologies can provide a competitive edge in the construction industry.

Upcoming Developments in Crawler Crane Hydraulic Pump Technology

As with many fields, hydraulic pump technology for crawler cranes is constantly evolving. Manufacturers are continually exploring new materials, designs, and features to enhance performance and durability. The integration of digital controls and smart technologies is also on the rise, offering a new level of precision and automation to crane operations.

In addition, there is a growing focus on environmental sustainability, which is leading to the development of more energy-efficient hydraulic pumps. These "green" pumps not only reduce the carbon footprint of crawler cranes but also offer cost savings in the form of reduced fuel consumption and lower operating temperatures.

In conclusion, the role of hydraulic pumps in the operation of crawler cranes cannot be overstated. They are the unsung heroes that enable these magnificent machines to deliver the heavy lifting prowess that powers global construction projects. As technology advances and the construction industry continues to grow, the science behind hydraulic pumps will play an ever more critical role in shaping the future of crawler cranes.

Leave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES